A na-ahụkwa teknụzụ Diamond waya ka a na-akpọkwa teknụzụ na-enweghị nkọ. Ọ bụ iji electropliting ma ọ bụ njikọta nke diamond nke diamond dị n'elu waya, waya mkpanaka na-eme ihe dị n'elu silicon mkpanaka iji mepụta ihe ịkpụ. Diamond waya nwere njiri mara nke ịgba ọsọ ọsọ, na-egbutu ihe ziri ezi na mfu na obere ihe.

Ugbu a, a na-ere otu ahịa CryMand Waya na-anabata SIICon Walher nabatara, mana ọ hụkwara na usoro nke nkwalite, nke na-acha ọcha na-acha ọcha bụ nsogbu kachasị. N'iburu nke a, akwụkwọ a lekwasịrị anya n'otú esi egbochi Diamond waya na-egbutu monocrystalline sifer Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet Velvet.

Usoro nhicha nke diamond waya na-egbutu modicon wafer bụ iji wepu silicon igwe na-egbu egbu site na igwe na-ekiri, wepu eriri roba, ma hichaa silicon roba. Ngwa nhicha ahụ bụ tumadi nhicha (igwe na-ehicha ihe) na igwe nhicha. Usoro nhicha nke ihe eji eme ihe bu: udiri ahihia-spray-ultrasoning na-asacha. Usoro nhicha nke igwe nhicha ahụ bụ: nri-ọcha na mmiri na-amịpụta - alkali na-asacha -ọ mmiri na-amịpụta-proboing mmiri) - na-eweli elu.

Ụkpụrụ nke velvet velvet na-eme

Monocrystalline silicon wafer bụ njirimara nke corrosion nke monocrystalline silicon wafer. Iwu mmeghachi omume bụ ihe eji eme ihe kemịkalụ ndị a:

Si + 2nah + H2o = Na2sio3 + 2h2 ↑

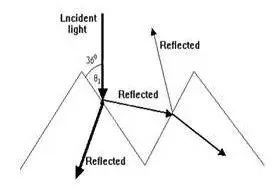

Na njiriwa, usoro a na-agba akwụkwọ bụ: Ngwọta NaEh maka ụdị Corrisoon dị iche iche, (100) na Monocry Corrosion Mgbe anamsotropic corrosion, mesịa guzobere n'elu (111) pene anọ, ya bụ "pyramid" (dị ka egosiri na eserese 1). Mgbe e guzobere ihe owuwu ahụ, mgbe ìhè ahụ na-emegharị pyramid na-agbasa n'otu akụkụ, ọkụ ga-apụta ìhè na akụkụ ọzọ, na -echeta echiche dị n'elu si silicon wafer , nke ahụ bụ, ọkụ ọkụ ọkụ (lee ọgụgụ 2). Kacha mma nha na Uniform "Pyramid" ihe owuwu, ihe ọnyà pụtara ìhè, na ala elu nke silicon wafer.

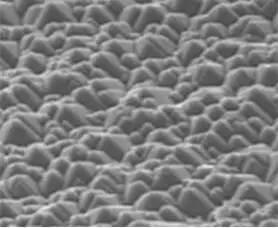

Ọgụgụ 1: Micromorphology nke Monocrystalline Silicon Wafer mgbe emepụtara alkali

Ọgụgụ nke 2: Ọnọdụ ọnya nke "Pyramid"

Nyocha nke otu kristal na-acha uhie uhie

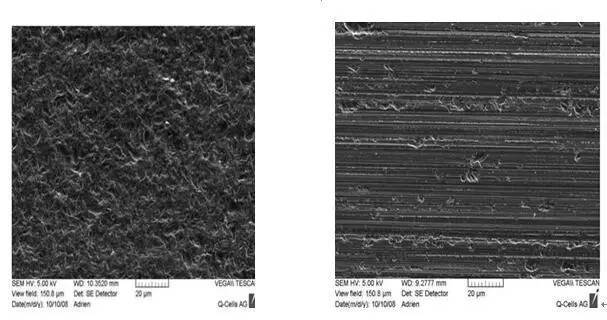

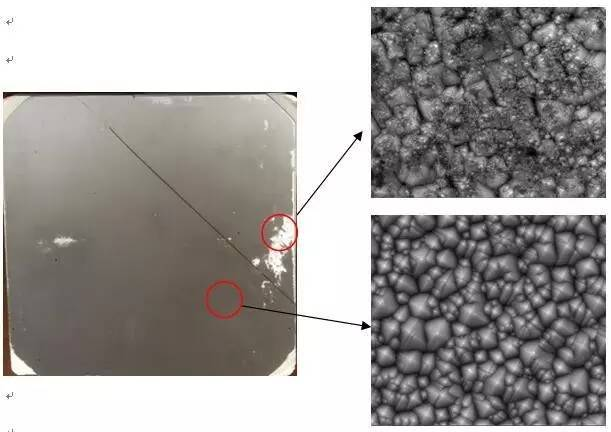

Site na inyocha microsron na-acha ọcha na White si silicon warfer, nke ahụ na-acha uhie uhie warfer na mpaghara ahụ bụ nke a na-enwe, ebe Pyramid nke suede Na White mpaghara otu silicon wafer e guzobere ka mma (lee eserese 3). Ọ bụrụ na a na-adọbisi ike n'elu monocystalline silicon wafer, elu ahụ ga-enwe usoro ndozi na ọgbọ niile dị elu na-adịghị mma, nke na-ebute na-atụgharị uche dị elu karịa mpaghara Ọnọdụ na-egosi ịdị elu tụgharịrị ma e jiri ya tụnyere mpaghara nkịtị na ihe nlele dị ọcha. Dịka enwere ike ịhụ ọdịdị nke mpaghara ọcha mgbe niile, ọ bụghị oge niile ma ọ bụ ọdịdị mgbe niile na nnukwu mpaghara, mana ọ bụ naanị na mpaghara mpaghara. Ọ kwesịrị ịbụ na mmetọ mpaghara dị n'elu si silicon wafer ewepụghị ya, ma ọ bụ ọnọdụ elu nke si si silocon wafer na-akpata site na mmetọ abụọ nke abụọ.

Ọgụgụ nke 3: Tụnyere ndịiche mpaghara mpaghara na Velvet White silicon wafers

Elu nke lire nke diamond waya dị larịị na-adịcha mma na mmebi dị obere (dị ka egosiri na eserese 4). E jiri ya tụnyere ngwa agha silicon wafer, ọsọ ọsọ nke alkali na nke diamond wafry elu si silicon wafer, yabụ mmetụta nke ahịhịa dị na velvet pụtara ìhè doro anya.

Ọgụgụ 4: (a) E micrograph nke mmiri cuthicon werfer (b) elu micrograph nke diamond waya bela

Isi mmalite nke diamond waya-bee silicon wafer

(1) coolant: isi ihe nke diamond waya na-egbutu ya, dispent, ramemagent na mmiri ndị ọzọ. Mmiri na-egbutu mmiri nke nwere ezigbo arụmọrụ nwere ezigbo nkwusi, mgbasa na ume nhicha dị mfe. Ndị na-asa ahụ na-enwekarị ihe ndị dị mma n'anya, nke dị mfe ihicha n'ime silicon wafer. Na-akpali akpali na mgbasa nke ihe ndị a na mmiri ga-emepụta ọtụtụ ụfụfụ dị ukwuu, na-ebute oke nju oyi, na-emetụta nsogbu oke, nke ga-emetụta ojiji. Ya mere, a na-ejikarị cooper a na-ejikarị ihe na-eme ihe. Iji hụ na arụmọrụ na-ezighi ezi, silicone ọdịnala na pollether na-abụkarị ndị na-adịghị mma. Ihe mgbaze na mmiri dị mfe ịgbasa ozi ma nọgide n'elu si silicon wafer na nhicha ahụ na-esote, na-ebute nsogbu dị ọcha. Ọ bụghịkwa nke ọma na ihe ndị bụ isi nke lowian, a ga-eme ya ka ọ bụrụ ihe abụọ, ndị na-eme ihe, dị ka ọnọdụ ụrọ, enweghị ike ịchịkwa ya Jiri na usoro nke ndị ọrụ Antifom, nwere ike ikwe ka ị na-eme mkpọtụ, na-eduga na mmụba dị elu, na-eduga na mmụba dị elu, ọ na-emekwa ka ọ dị ala, n'ihi ọnụ ala nke akụrụngwa na-emebi Ihe ndị, yabụ, ọtụtụ n'ime ụlọ na-acha uhie uhie na sistemụ a usoro; Onye ọzọ na-eme ihe nkiri ọhụrụ, nwere ike ịdị mma na isi ihe, enweghị mgbakwunye na-egbochi ọnụ ọgụgụ ya, nwere ike ịchịkwa oke ya, ihe omume dịkwa mma ịme ya, na-ejikwa usoro dị mma, ya Enwere ike ịchịkwa mkpokọta na ọkwa dị ala, na Japan na ndị na-eme ihe ole na ole na-eme usoro usoro a, n'ihi uru ọnụahịa ya adịghị doro anya.

(2) gluu na ụdị resin: Na usoro nke na-egbu egbu nke diamond, ndị si silon wafer na njedebe njedebe a anaghị ebipụ, na mmalite nke diamond Ware amalitela ịkpụ ya na efere resin, ebe ọ bụ na Silicon Road Gluu na ngwaahịa resin bụ ihe dị nro bụ ihe dị nro efere dị ala, ọ nwere ike iwepụta oge na-akpụ akpụ ma mee ka ọ dị nro ma na-agbazekwa ya, na-eme ka ọ dị ọcha nke diamond belatara, ma ọ bụ nke si si silicon wafe na Ọ na-esiri gị ike, o siri ezigbo ike ịsacha, mmetọ ndị dị otú ahụ na-eme n'akụkụ ihu silicon wafer.

(3) Silicon ntụ: Na usoro nke diamond waya ga-amị ọtụtụ silicon ntụ ntụ ga-esiwanye elu, mgbe ntụ ntụ ahụ buru ibu, ga-agbaso silicon n'elu, Diamond Waya nke silicon nha nha na nha na-eduga nfe ka ọ dị mfe iji na silicon elu, mee ka o sie ike ịdị ọcha. Ya mere, hụ na mmelite na ogo dị mma nke jụrụ oyi ma belata ntụ ntụ ahụ na jụụ.

(4) nhicha nke diamond na-eji ngwa agha na-eji ngwa agha na-eji ngwa agha, wdg, otu diamond cryting teknụzụ site na usoro ịkpụcha, na-etolite a Zuru ezu nke ahịrị, coolant na cutting cut nwere nnukwu ọdịiche, yabụ na njikọta nhicha, nhicha, wdg kwesịrị maka idozi mmezi. Akụkụ dị ọcha bụ akụkụ dị mkpa, a na-ahụ maka ịchafụ azụ, kwesịrị ịdị mma maka ihicha si silicon waya, ihe mejupụtara ya na ebe a na-edebe ihe na-eme ka ọ dị elu, were ya usoro nhicha. Dị ka m kwuru n'elu, ihe mejupụtara ihe ndị na-ejide onwe ya na-adịghị mkpa na ịkpụ ngwa agha.

(5) Mmiri: Cleard Waya, ịsacha ma hichaa mmiri na-egbu egbu nwere adịghị njọ, ọ nwere ike ịbụ ndị mgbasa ozi si silicon wafer.

Belata nsogbu nke ịme ntutu ntutu na-acha ọcha na-acha ọcha na-egosi aro

(1) Iji dicha mma nke nwere ezigbo mgbasa ozi, a chọrọ ka ị jiri ya na-agbachitere ndị na-eme ihe na-adịghị ala ala iji belata nsị nke ngwa ahụ dị n'elu si silicon wafer;

(2) Jiri gluu dị mma ma na-emegharị ya iji belata mmetọ nke silicon wafer;

(3) A na-eji mmiri dị ọcha mee ka mmiri dị ọcha mee ihe iji hụ na enweghị adịghị ọcha na mmiri eji eme ihe;

(4) maka elu diamond waya belata silicon wafer, jiri ọrụ na ihicha ọcha dị mma karịa nchara;

(5) Jiri dayamọnd na-agbagha dị n'ịntanetị iji belata ntụ ntụ silicon na-emepụta ihe, iji chịkwaa ntụ ntụ nke si silicon wafer nke wafer. N'otu oge ahụ, ọ nwekwara ike ịbawanye mmelite mmiri nke mmiri, na-asọ na oge na a na-asa, iji hụ na a na-asa ahụ silicon na-asa ya n'oge

(6) Ozugbo akwadoro silicon wafer na tebụl nhicha ahụ, a ga-emeso ya ozugbo, ma debe silicon ga-ewepụta mmiri n'oge nhicha ahụ.

(7) Silicon wafer na-eme ka mmiri mmiri dị na usoro nke degumming, ma enweghị ike ịkpọ nkụ. (8) Na usoro nhicha nke silicon wafer, a na-ekpughere oge a ga-ebelata ikuku dị ka o kwere mee iji gbochie mmepụta ifuru n'elu si silicon wafer.

(9) Ndị ọrụ nhicha ahụ agaghị akpọtụrụ elu nke silicon wafer n'oge a na-eme ihe nhicha ahụ, ma ọ ga-eyi uwe mkpuchi roba.

(10) na-ezo aka [2] Principlekpụrụ ya yiri nke nhicha nhicha ahụ (a na-akpọkarị ya dị ka mmiri 1) nke semiconductor silicon wafer. Isi ihe eji eme ya: Ihe nkiri oxidation na si silipon wafer na-etolite site na oxidation nke h2o2, nke na-eme ugboro ugboro. Ya mere, irighiri mmiri ahụ na-agbakwunye na si silicon ntụ, resin, igwe, wdg) na-ada n'ime mmiri nhicha ahụ na akwa mkpuchi corrosion; N'ihi oxiding nke H2o2, ihe ndị dị na ya na wafer dị na CO2, H2O ma wepụ. Usoro nhicha a bụ Sọnicon wafer ndị na-eji usoro a iji hazie monicon wafer, sililon warry na ndị na-emepụta ụlọ ọrụ batrị na-acha ọcha. Enwekwara ebe nrụpụta batrị ejirila usoro nhicha dị elu nke yiri nke ahụ, na-ejikwa ọdịdị nke velvet ọcha. Enwere ike ịhụ ya na a na-agbakwunye usoro nhicha a na Silicon waferd usoro iji wepu si silicon wafer iche iche iji dozie nsogbu nke ntutu dị ọcha na njedebe batrị.

mmechi

Ka ọ dị ugbu a, mbelata diamond abụrụla teknụzụ nhazi bụ ihe na-enye nsogbu na-enye nsogbu nke Velvet White na ndị na-ere batrị na Diamond Waya na-egbu Silicon wafer nwere ụfọdụ iguzogide. Site na nyocha ntụnyere nke mpaghara ọcha, ọ bụ nke a na-akpata site na nsị n'elu si silicon wafer. Iji gbochie nsogbu nke silicon wafer in sel, akwụkwọ a, akwụkwọ a nwere ike isi mmalite nke mmetọ nke silicon wafer, yana aro na-eme ka mma na usoro dị na mmepụta. Dabere na ọnụ ọgụgụ, mpaghara na ụdị ọcha ntụpọ, enwere ike ịlele ma meziwanye ihe. A na-atụ aro ka ị jiri hydrogen peroxide + alkali nhicha. Ahụmahụ na-aga nke ọma gosipụtara na ọ nwere ike igbochi nsogbu nke Diavon Waya na-eme Silicon wafen na-eme velvet Whitening, maka ntụaka nke ụlọ ọrụ na ndị na-emepụta ihe.

Oge post: May-30-2024